What are the main application areas of high-performance plastics?

High-performance plastics have many unique characteristics and advantages, so they have a wide range of applications in many fields. Here are some of the main application areas: Aerospace: In this field, high-performance plastics are used to manufacture lightweight, high-strength and high-heat-resistant parts, such as structural parts, engine parts, seats and interiors of aircraft and spacecraft. Automotive: The use of high-performance plastics in the automotive industry is increasing for the manufacture of lightweight, high-strength automotive parts, such as bumpers, body panels, engine parts, fuel systems, and wire insulators. Electronic appliances: In this field, high-performance plastics are used to manufacture high-temperature, high-insulation, and corrosion-resistant components, such as wire insulators, electronic components, battery separators, and semiconductor packaging. Medical devices: High-performance plastics are widely used in medical devices, such as surgical instruments, dental equipment, diagnostic equipment, implants, prostheses and orthoses. Sports equipment: High-performance plastics are also used to manufacture various sports equipment, such as skis, golf clubs, fishing rods, bicycle frames, etc., because these materials are light and durable. Packaging: High-performance plastics can also be used to manufacture various packaging materials, such as food packaging, pharmaceutical packaging, cosmetic packaging, etc., because these materials have good barrier properties, corrosion resistance and recyclability. These are just the main application areas of high-performance plastics. In fact, with the advancement of science and technology and the improvement of people's requirements for material performance, the application areas of high-performance plastics will continue to expand.

2024/02/26

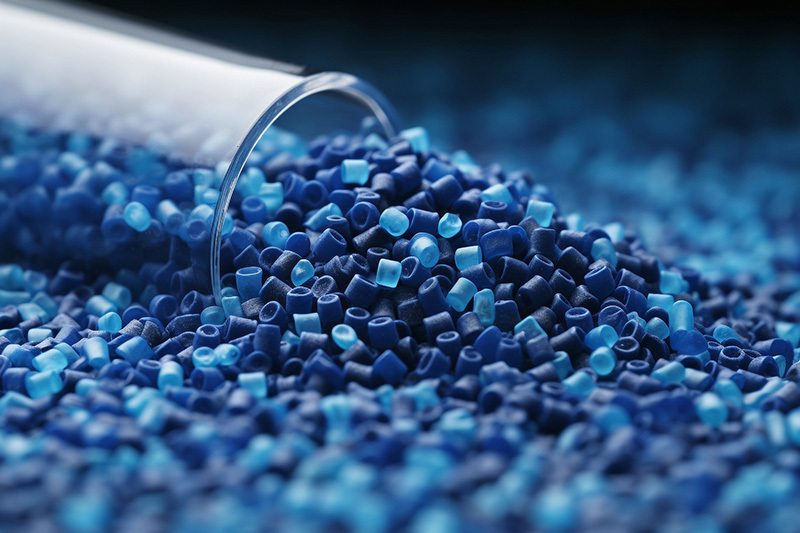

High-performance plastics are a class of plastic materials with excellent physical, chemical and mechanical properties. They usually have the characteristics of high strength, high rigidity, high wear resistance, high chemical resistance, high thermal stability, etc., and can maintain their ideal mechanical, thermal and chemical properties in harsh environments. These plastic materials are often used to manufacture components in high-performance applications, such as aerospace vehicles, semiconductor manufacturing equipment, automobiles, electronic appliances, medical devices and other fields. Common high-performance plastics include polyimide (PI), polyether ketone (PEK), polyphenylene sulfide (PPS), liquid crystal polymer (LCP), polysulfone (PSU), polyetherimide (PEI), etc. These plastic materials have different characteristics and can meet different application requirements. For example, polyimide has excellent flame retardancy, scratch resistance and chemical corrosion resistance, and is usually used to manufacture high temperature and high performance applications; polyether ketone has low smoke, halogen-free and other characteristics, and can be used to manufacture parts in the field of electronic appliances; polyphenylene sulfide has excellent dimensional stability, electrical insulation performance and high temperature resistance, and is usually used to manufacture parts in high temperature and high humidity environments. In addition to the above several common high-performance plastics, there are many other high-performance plastic materials, such as polyamide imide (PAI), polyimide ketone (PIK), polybenzimidazole (PBI) and so on. These plastic materials are also constantly being developed and improved to meet changing market demands. In general, high-performance plastics are a very important class of plastic materials, and they have a wide range of applications in many fields. With the continuous progress of science and technology and the continuous development of the market, the application prospect of high-performance plastics will be more and more broad.

2024/02/26

Modified plastics: rapid growth in demand, broad space for development

The overall demand for modified plastic raw materials in the market is very high. It is estimated that the overall market has reached 13.61 million tons, and consumption is also growing rapidly. The compound annual growth rate of 14.3 percent since 2004 is higher than the 9.6 percent for plastics. Modified plastics are widely used in many industries, such as automobiles (23.5 percent) and household appliances (37.0 percent), because they have product advantages that ordinary plastics do not have. Therefore, from the perspective of application, it can be said that they have broad prospects.

2023/12/25

Control of temperature, pressure and speed parameters in injection molding process

Melt temperature is very important in the injection molding process. The melt temperature can be measured at the nozzle of the injection molding machine, or roughly estimated using the air injection method. The temperature setting of the barrel depends on the melting temperature of the plastic melt, screw speed, back pressure, injection volume and injection cycle. If the operator does not have experience with a particular plastic, the test should begin with the lowest allowable temperature setting. In order to facilitate precise control of the melting temperature, the barrel is usually divided into a plurality of heating zones, each of which can be set to a different temperature. If the injection time is long or the operation is at high temperature, the temperature of the first zone should be set to a lower value, which will prevent premature melting and separation of the plastic. Before starting the injection molding process, make sure that the hydraulic oil, hopper sealer, mold and injection cylinder are at the correct set temperature.

2023/12/25

How much impact does the automotive market have on the injection molding machine industry?

In the injection molding machine industry, automotive is a single market that can drive all stakeholders. Regarding the relationship between the automobile market and the injection molding machine market, the industry has expressed this statement. Taking the US injection molding machine market as an example, stimulated by the volume of automobile transactions, American machinery manufacturers are optimistic about the machinery market.

2023/12/25

Matching relationship between pigments, plastic raw materials and additives

The colorants used in the masterbatch must pay attention to the matching relationship between colorants, plastic raw materials and additives in the masterbatch technology. The key selection points are as follows. 1. The colorant cannot react with resins and various additives, has strong solvent resistance, low mobility and good heat resistance. In other words, the masterbatch cannot participate in various chemical reactions. Carbon black can control the curing reaction of polyester plastics, so carbon black materials cannot be added to polyester.

2021/11/12